if anyone can, dupra can!

DRUPA 2024 –

HIT OR MISS?

DANIEL BRUNTON LOOKS AT THE GLOBAL PRINT EVENT THAT RAN IN DÜSSELDORF FROM 28TH MAY TO 8TH JUNE.

It had been a long and, for many, unsettling eight years since drupa 2016. Expectations were high from the organisers, Messe Düsseldorf and the drupa Technical Committee; exhibitors needed a solid event to cement the show’s position as the leading global print expo and justify the (in many cases) heavy cost associated with exhibiting equipment at the industry’s ‘Olympic Games’.

But how do we assess the success of a show as big as drupa? Number of visitors? Number of deals done? Contacts made?

This is a really tough question to answer. If we look at the official numbers, it is hard to argue drupa 2024 has been a success, as it missed its targets by a wide margin; Messe Düsseldorf reported 170,000 people attended – that is almost 35% down on 2016 (260,000 visitors) and more importantly, falling significantly short of the anticipated 200,000 people the organisers were saying would come based on pre-registration. It shows the danger of ‘bigging up’ an event in this day and age.

Do numbers really matter though? Surely the age-old missive of quality over quantity is never truer. From the exhibitors I spoke to who are active in the folding carton and corrugated industry (roughly 90 companies nestled in an event boasting over 1,500 exhibitors), the feedback was broadly positive.

High level participation of senior executives from a wide range of converters from all over the world, but certainly not in the numbers of 2016. It could be argued that a similar number of companies visited, choosing to bring fewer delegates – the cost of air travel and hotels is undoubtedly higher than in the past, possibly forcing converters to think hard about how many people to send. The upside of that is that the right people came, less tyre-kickers for sure.

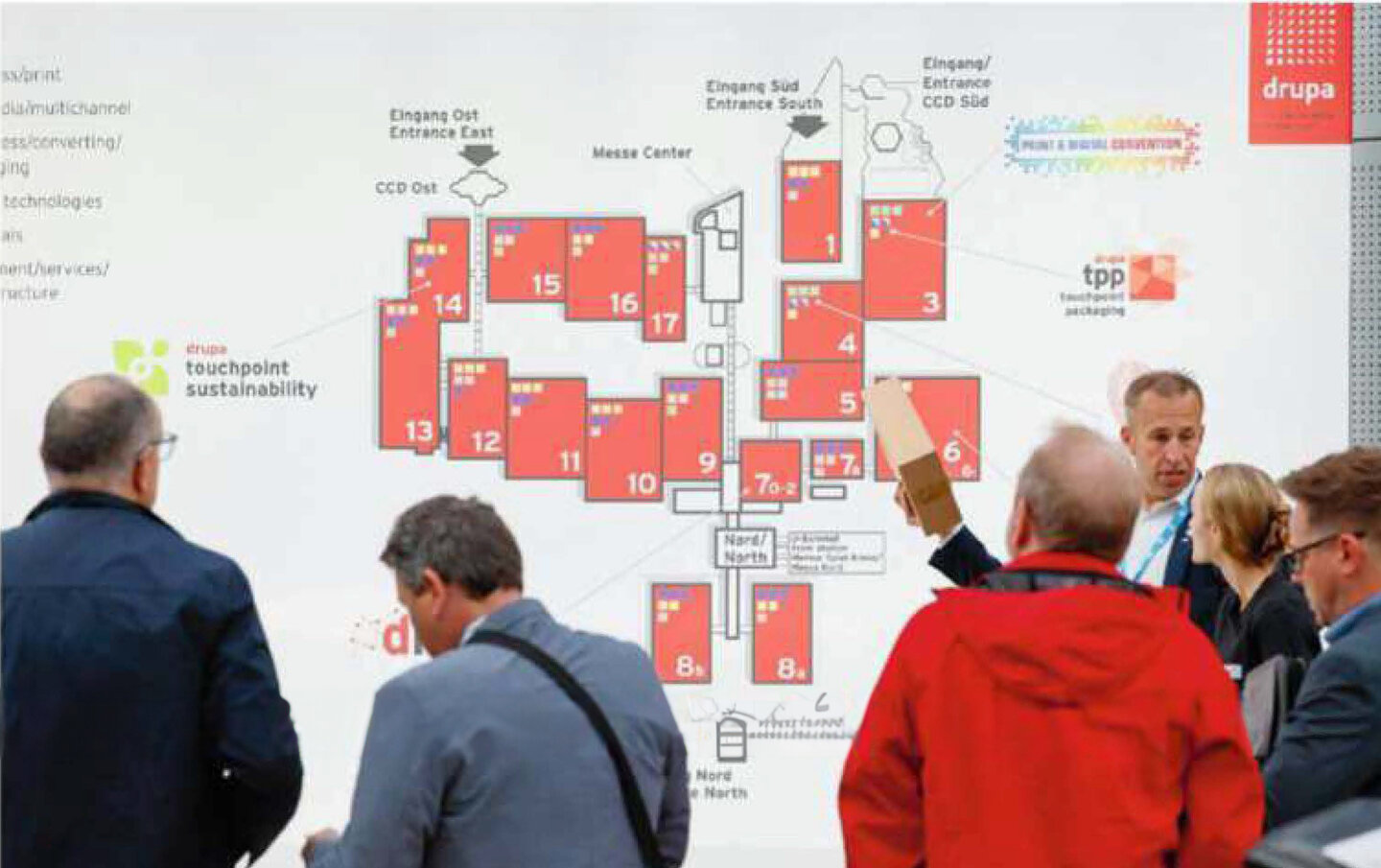

With over 1,500 exhibitors, you would expect full halls – but there were certainly some halls that felt very flat, lacking in activity, and far too many ‘networking’ areas (areas designated as stands for exhibitors who decided not to show) and far too many walls moved inwards and long expanses of no booths at all; a definite nod to the fact that they should reduce the hall count by at least two halls in my opinion.

There was also an overwhelming number of Chinese exhibitors, many of whom had small booths, a few brochures, a person reading their phone and only really there due to state-funded overseas promotional grants. In all honesty, this needs to stop, as there is zero value for the visitors and just takes up even more space that could be consolidated. But I understand that Messe DOsseldorf needs to make money doing an event of this scale.

Of course, there is always the event hype and post-event back slapping, with release after release showing smiling customers shaking hands on a booth or atop a machine - but we need to look past this! Those deals were already in the sales pipeline and would more than likely happened this year whether there was a drupa or not!

Let's face facts, the COVID-19 pandemic taught us all some very important lessons - lessons that I am glad to say have stayed with us. Let me explain; cast your mind back to the dark days in spring 2020 when the world stopped revolving; suppliers had to react as quickly as possible and work out how to keep in front of their customers when they could not physically meet. In general terms, they had to learn how to market themselves again, properly this time. And the majority succeeded, doing a better job now than they have ever done (almost to the point where the trade press is on a knife edge of retaining its relevance!). The result of this great slew of content, online exhibitions (including our own, award-winning ConneXion!) a promotion leads us to the next important lesson – printers and converters are now better ‘educated’ on the latest technology thanks to video content, LinkedIn and direct messaging of content that is specific to them. In basic terms, suppliers are providing the correct level of content to a target audience who is happy to listen, watch and learn… without having to leave their factory!

As the earth started spinning again in 2022, the bigger OEMs realised that they were still a couple of years away from the next drupa, but many were keen to showcase equipment in light of the boom in e-commerce and the growing need for fibre-based packaging as the ensuing environmental laws and guidelines laid out a great future for the sector. Open House events rolled out, literally month after month! The engagement levels were frenetic (but don’t forget, people were just happy to be traveling again and meeting people!) and suppliers had full order books, of course bulked up due to long lead times due to the supply chain issues of 2021-2023. But they were doing business, and lots of it – without attending shows.

drupa is essential

You’ve spent the last few minutes, reading my views on how drupa missed its targets. To be brutally honest, they should have consolidated several halls, reduced the event to eight or nine days and really looked at the volume and quality of the smaller exhibitors.

Although I was rather underwhelmed by the lack of real innovation, I am not surprised – drupa ‘reveals’ of machines that had already been in the field for two years is just the result of OEMs understanding how to keep its business moving forward. They don’t need a four year machinery development cycle, as they have a platform to communicate. So no, I wasn’t wowed by any one company or any one product. I remember I christened the event in 2016 as the ‘digital print on packaging’ drupa – this time, it felt like it was more of a software and plant automation focus, with plenty of chat about AI, but no one really able to show how AI will affect our sector.

But what I would say is that visitor numbers reflected a consolidating and changing industry. And most important of all, drupa did succeed in the most critical area – networking and sharing of information that sparks the ideas and innovations that will secure growth in our industry. It needs to continue doing this – bringing together like minded suppliers and converters and keep our industry relevant.

Only time will tell whether drupa 2024 was a success. There will be a four year wait until the sector gathers again in Düsseldorf – let’s hope that the industry gets behind it once more, exhibitors and visitors alike, as the reality is that there is nothing else like it anywhere in the world – and Messe Düsseldorf certainly know how to host us!

And for the packaging community, drupa will become your home too – I think you can expect a lot more packaging machinery OEMs, software and ancillary suppliers will jump in with both feet, as the print and packaging sectors converge. Beers in Altstadt in 2028? I’ll certainly be there.

read more

Qualvis ready for drupa machine delivery

Fresh from the manufacturing line at Koenig & Bauer Duran, a new Omega Alius 90 folder gluer shown at drupa is on the next leg of its journey to a new home in Leicester, UK. Along with a brand new Rapida 106 press, the Omega Alius 90 folder gluer is part of a major investment by Qualvis Print & Packaging.

Qualvis already operates a seven-colour Rapida 106 with twin coaters and an lberica cutter creaser. However, the new configuration has been described as something 'entirely different'. It will meet a real need in the market. according to insiders, but will remain undisclosed for competitive advantage.

"All I can reveal about the new press is that it is quite special. Our product designers have worked closely with Qualvis, under strict non-disclosure, to develop a one-of-its-kind capability that will give Qualvis a jump on the market." said Chris Scully, Managing Director, Koenig & Bauer UK.

In a statement from the Joint Managing Directors of Qualvis,

Lisa Smith and Marcus Short, they said, "We're excited to be

installing a special Koenig & Bauer press configuration, it has

been a true collaboration to get to this point and we can't wait to

showcase our new offering. Koenig & Bauer truly aligns with our ethos of innovation and is looking to push the market forward in both sustainability and printing effects."

They continued, "Not only have we partnered with K&B for our new press but we'll also be installing the new Omega Alius 90 folder gluer coming direct from drupa. The first of the new model to market will offer high speeds and intelligent automatic setup. This new folder gluer complements our requirements perfectly. These purchases complement the recent

investment strategy started two years ago, that includes not only

machines, but technology and a solar energy investment to further reduce our carbon footprint. This completes phase two of our longterm investment programme and allows us to continue to focus on sustainable cutting-edge innovation and first-to-market solutions, which is our passion, whilst increasing

capacity to allow for growth which has been exponential over recent years. Extremely exciting times."

"Qualvis make it very for customers to do the right thing in terms of sustainable packaging. From organic vegetable inks to board supply and recycled and recyclable plant-based materials, their whole packaging production is vegan friendly," adds Scully. "At Koenig & Bauer, one of our main strengths is our ability to

innovate and develop technology on a project-by-project basis. We're pleased that they chose us to be their innovation partner on this project."

back to top